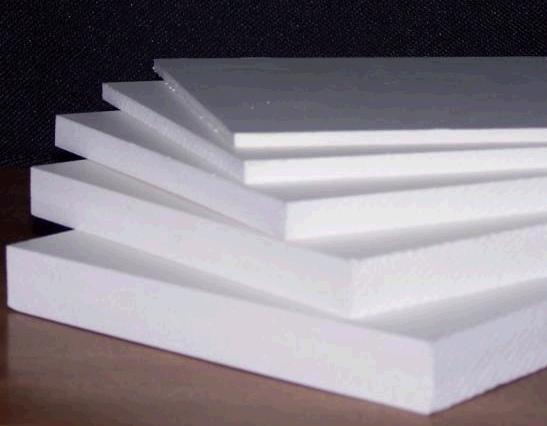

Lrb Mttress

Lightly resin bonded Mineral wool mattresses (LRB) consists of fine fibers spun from selected rocks melted at high temperature and bonded with a thermosetting resin. They are Machine laid fiber lay pattern and are baked to form mattresses of predetermined density and thickness. Mattresses are then slit and stitched to specified dimensions . It has controlled thickness and density resulting in predictable heat losses. Dhanbad Rockwool mattresses manufactured from selected rocks to State of the Art Specification fully conform to national and international standards such as IS : 8183 - 1993 BS : 3958 Part - 3 ASTM:C592 - 80

Technical Data :

APPLICATION

LRB mattresses are used for Hot & Cold insulation to conserve energy It is used in the thermal insulation of large vessels, boilers, , equipment, ducts, flanges, valves and plants operating at high temperatures.

SERVICE TEMPERATURE

-50 to + 750 DEGREE CENTI GRADE

AVAILABILITY

Standard Dimensions : 1.640 X 1.220 M

Thickness - MM : 25,40,50,60,65,75,100

Density (Kg/M3) : As per IS:8183

THERMAL CODUCTIVITY

Mattress has extremely low K values for wide range of temperature. Typical thermal conductivity values for various densities and mean temperature are shown in the graph.

FACING

DRW /ECOROCK LRB Mattresses are available with wired mesh on one or both sides in SS or GI.

MOISTURE

Non-hygroscopic, non-capillary and does not absorb any moisture from the air. Moisture has no effect on the stability of the mattresses.

FIRE RESISTANCE

Non-combustible when tested in accordance with BS - 476 part - 4 and ASTM E - 136. Class1 when tested in accordance with BS - 476 part 7, (ASTM E- 84).

PACKING

DRW/ECOROCK LRB MATTS mattresses are packed in HDPE bags.

COROSSION RESISTANCE

Mattresses do not cause, initiate or promote any kind of corrosion

FLEXIBILITY

Mattresses are very flexible. They will essentially retain thickness while conforming to any irregular shape. Retention of fibers by wire mesh prevents cracking or breaking of mattresses.

BENEFITS OF DRW/ECOROCK INSULATION PRODUCT

Incombustible Good acoustic properties